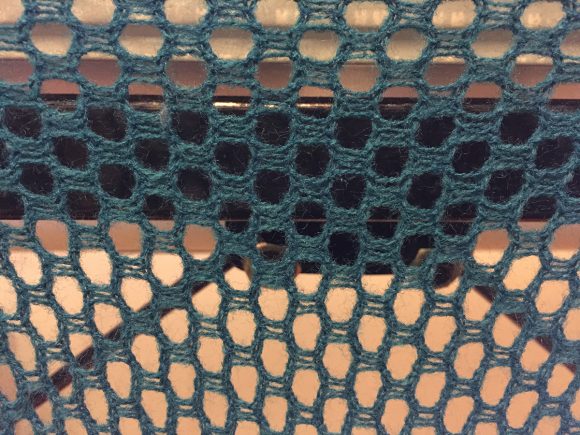

This scarf was knit on my Knitking Compuknit V (Brother KH-965) computerized knitting machine using Brother Stitchworld patterns #104 and #105. I used a extremely fine, laceweight yarn from National Spinning Co. in dark teal Uybran acrylic at tension number “3”. It blocks nicely when steam ironed, and the resulting fabric has no edge curl.

Here’s how to create your own:

1. Cast on 90 needles (needles 45 to 45). I used a closed, crochet, or chain, cast on, it makes the seaming easy when it’s time to join the scarf edges.

2. With the K carriage knob set at “NL” for plain knitting, knit 6 rows in stockinette.

3. Program pattern #104 into your machine.

4. Knit with the lace carriage for 120 K carriage rows.

NOTE: It’s tricky to describe how many rows to knit when using a lace carriage because the pattern can call for different numbers of lace carriage passes between K-carriage passes, and there is no row counter for the lace carriage. So, I’ll use the number of rows the K carriage moves back and forth.

TIP: If you’ve never machine-knit lace before, you move the lace carriage from left to right, past the turn mark (just like regular knitting with the K carriage), across the needles until no needles are selected.The lace carriage always makes at least two passes across the bed, one from left to right, then back to the left side of the machine. Then the K carriage makes two passes, knitting two rows each time between lace passes.

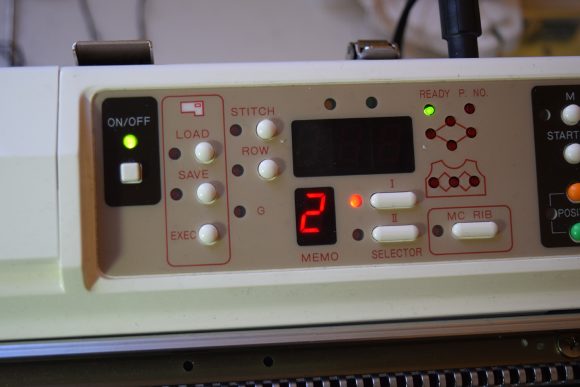

Sometimes a pattern will require you to make many, many passes with the lace carriage to transfer all the stitches.If you are knitting on a Brother or Knitking with a working original board, you’ll see a “2” in the memo display when you need to use the K carriage. If you’re using AYAB, or another machine knitting hack, move the K carriage once no more needles are selected.

NOTE: I haven’t translated these lace pattern image files for AYAB yet, but I’m hoping to get to it soon.

5. Turn the K-carriage knob to “NL” for plain knitting.

6. Knit 6 rows in stockinette.

7. Program pattern #105 into your machine.

8. Knit with the lace carriage for 120 K carriage rows.

9. Knit 6 rows in stockinette.

10. Punch in pattern #104, knit 120 K carriage rows.

11. 6 rows stockinette.

12. Enter pattern #104, knit 12o K carriage rows.

13. Knit 5 rows in socking stitch.

14. Loosen the tension to 10 and knit one final row.

15. Bind off by hand or with a Brother linker accessory.

16. Remove the scarf from the machine.

17. Join the scarf’s top and bottom edges by hand with a tapestry needle or use a linker.