This spring when the pandemic began and local healthcare workers were experiencing PPE (personal protective equipment) shortages, I joined up with the global group OSMS (Open Source Medical Supplies), the local RI group C19-RI Rapid Solvers, and Providence, RI artist China Blue to fabricate PPE for donation to Rhode Island health care workers.

My totals for personally fabricated PPE are as follows:

- 1232 3D printed face shields

- 75 sewn masks

- 93 CNC routed ear savers

- 235 3D printed ear savers

- 120 door grabers/COVID keys

Face Shields

Design

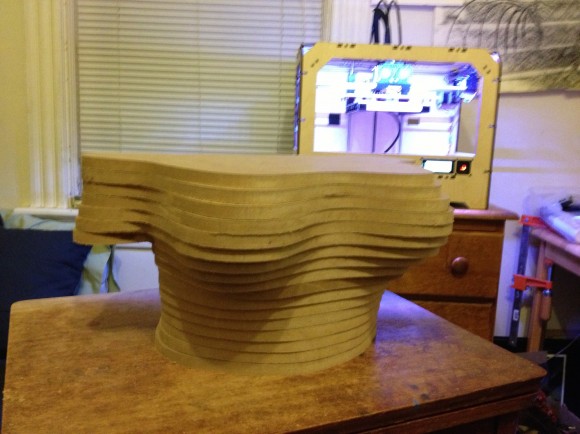

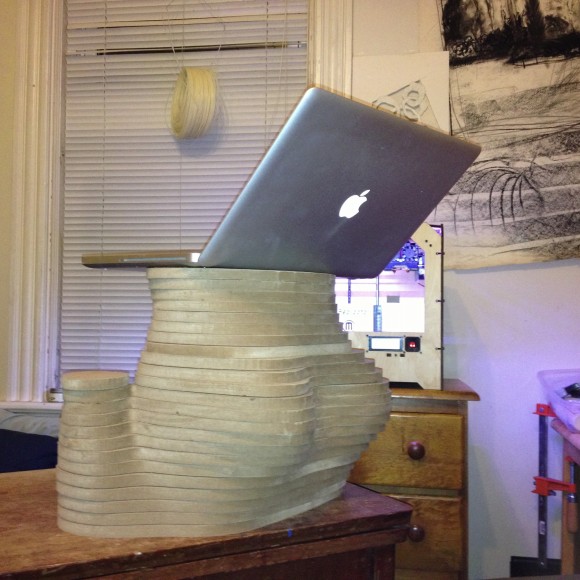

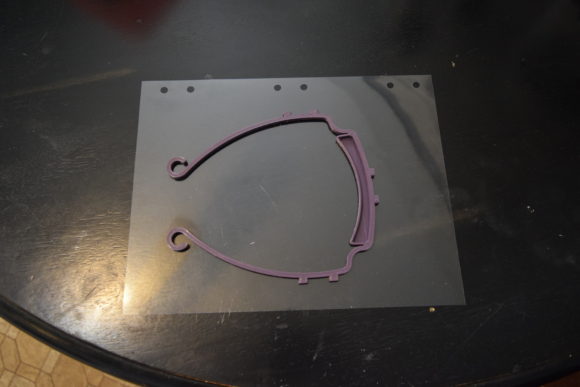

The face shield I produced was the 3D Verkstan version, designed by Erik Cederberg. I found this design to be both comfortable, quick printing, and it can “stack” for overnight print jobs. and I printed all the face shields on two Ultimaker 2 3D printers in PLA plastic.

Materials

The headband can be printed in PLA or PETG material. I heard from several Maker organizations that PETG is preferred if the face shields will be reused and sterilized between uses, but that if you are printing single-use face shields, PLA will be adequate. However, I was unable to purchase PETG, because all of my usual suppliers were sold out. In addition, I had a lot of PLA lying around and so that’s what I used.

The clear material that shields the face was comprised of clear binding covers, letter size, 7.5mil, purchased online.

Sterilization

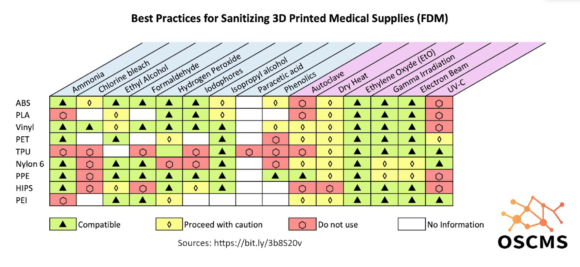

Although PLA face shields were considered “single use”, the demand was great and supplies were short. I knew health care workers would try to sterilize the face shields, so I used the OSMS guide on 3D printed materials to create personalized sterilization guides for my donated shields.

Printer Modifications

In order to print faster, I modified my Ultimaker 2 printers with the Olson Block nozzle upgrade and used a .8mm nozzle. This larger size nozzle, (a typical 3D printer nozzle is .4mm), allows more plastic to flow through it, enabling larger layer heights and faster 3D prints.

Ear Savers

I 3D printed the Surgical Mask Tension Release Band for Ear Comfort & Extended Use designed by Davis Becker from the NIH 3D printed model repository. Here is my sterilization guide for this item in PLA.

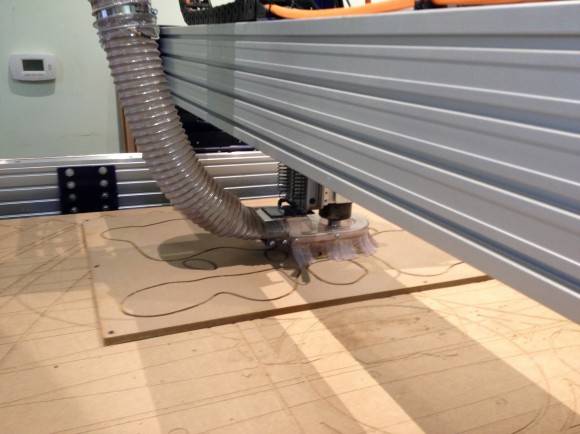

I CNC routed the Glowforge ear saver design in acrylic. Here is my sterilization guide for this item in acrylic.

Cloth Masks

I tried numerous cloth mask patterns before I finally settled on what I think is the best out there, the Iris Luckhouse Hybrid Cloth Mask. It has a unusual design that incorporates a inverted pleat over the nose bridge that keeps the mask fitting air-tight without any gaps. I also added adjustable ear loops to the design.

Before I was able to buy adjustable, elastic ear loops (elastic was sold out everywhere due to the makers constructing DIY masks in the early days of the pandemic), I made the cord ties on my knitting machine.

Door Grabbers/COVID Keys

Made to avoid touching contaminated doors and keypads, these door grabbers are made of 3D printed PLA plastic. This design was created by Gary Meyers and is available on Thingiverse.